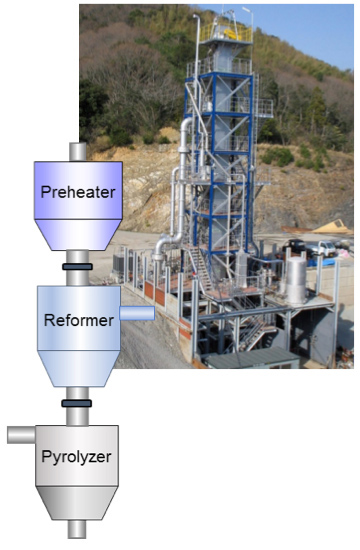

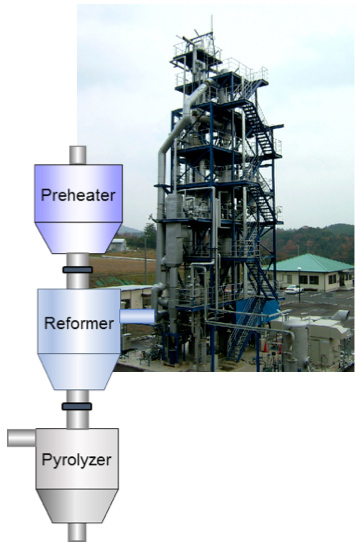

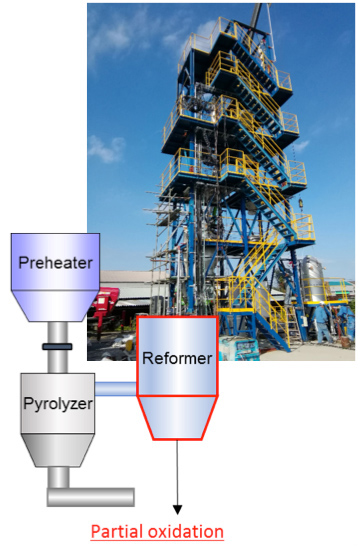

After 18 years of R&D, we developed our own process of biomass conversion and succeeded in producing hydrogen gas from biomass resources.

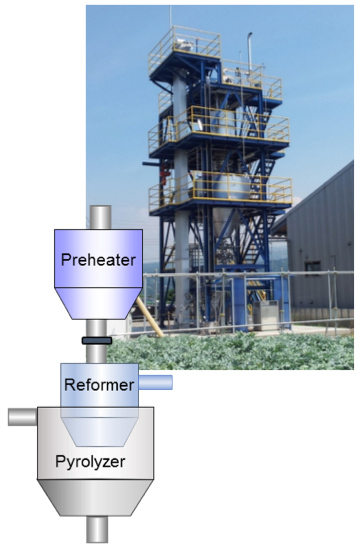

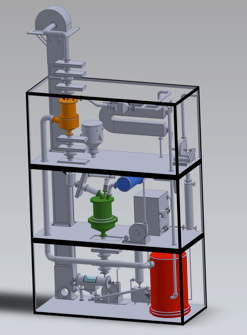

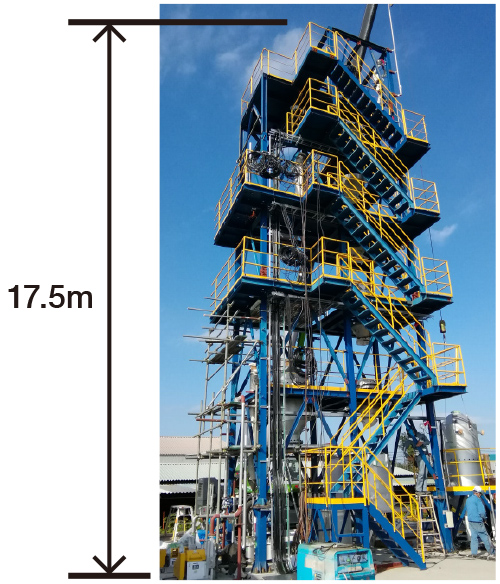

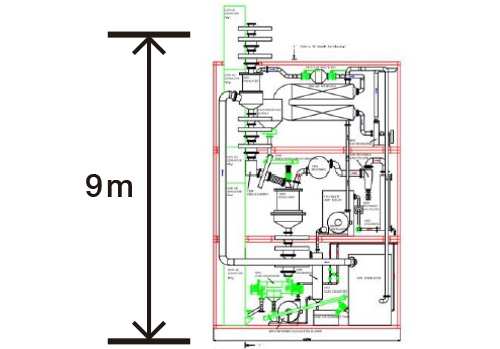

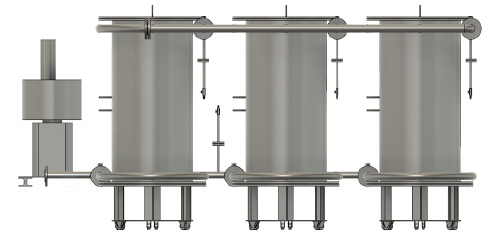

Furthermore, we are currently working on the development of a unit type module (AGM: container accommodation type) that can be mass-produced, in addition to a conventional large plant type (AGP), whose construction cost is high. We have received orders for prototype units respectively in the United States and Japan (as of March 31, 2020).

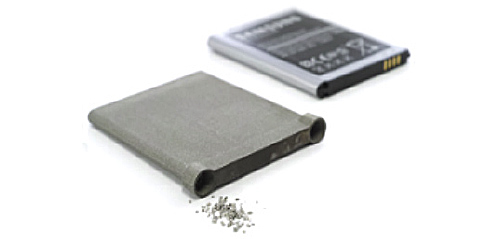

Meanwhile, in cooperation with the Faculty of Science, Tokyo University of Science, we have been working on the development of a hydrogen storage alloy system that can store, transport and use hydrogen produced by AGP and AGM’s ancillary facilities (gas purification equipment, 2-step PSA, etc.) and BLUE process at normal temperature and low pressure.